Misalignment Problems? Diagnosing Improper Dowel Pin Installation in Fixture Design

7 Hilarious Mishaps from Improper Dowel Pin Placement

Picture this: a manufacturing plant buzzing with activity when suddenly a machine hiccups and grinds to a halt. The culprit? A pair of misaligned custom dowel pins, literally causing chaos in the assembly line. Operators scramble as components refuse to fit together, leading to a humorous yet frustrating day of rework. The unfortunate operator responsible for the placement might still hear the ribbing from their team as they recall “that one time” when the dowel pins were installed upside down, resulting in a charming jigsaw puzzle instead of a cohesive structure.

Or consider the tale of a dowel pin manufacturer tasked with creating precision fixtures for high-end electronics. Shortly after installation, a batch of products began malfunctioning. Investigation revealed that the root of the issue lay in improperly placed dowel pins, making alignment a fantasy rather than reality. The solution? A full afternoon of team bonding over hilariously bad design sketches and a collective vow to verify dowel pin placement twice before proceeding. Each story serves as a reminder that what may start as a simple mistake can spiral into a comedic saga that lasts well beyond the workshop. Get more details on dowell pin manufacturers.

Can You Laugh at These Painful Mistakes?

Picture this: a workshop filled with the sounds of drill bits and excitement as engineers put together a new fixture. Suddenly, one brave soul realizes their riveting dowel pin is installed askew. Instead of observing proper alignment, they created a brand-new art installation. Think dowel pin Picasso, where chaos meets creativity. Custom dowel pins could have prevented this mishap, but alas, a moment of carelessness transformed precision engineering into an abstract disaster worthy of the best slapstick comedy.

Another classic blunder involves an ambitious project manager who mistook the blueprint for a coffee filter. The result? A pristine assembly fixture that resembled Swiss cheese rather than a cutting-edge manufacturing tool. As the laughter echoed around the shop, everyone realized the lesson: a reputable dowel pin manufacturer can be the unsung hero in ensuring correct placement. Every successful installation hinges on attention to detail. Each misplacement becomes fodder for stories shared over lunch.

Tools and Techniques for Correcting Dowel Pin Issues

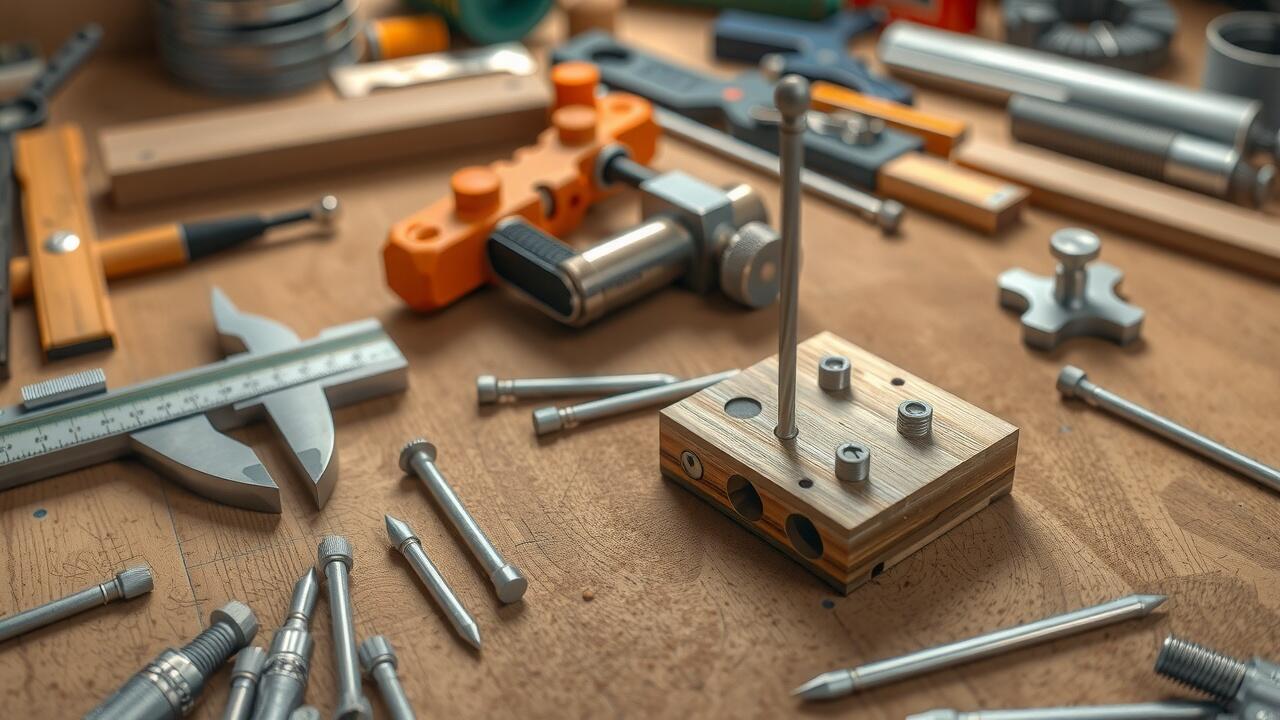

When facing dowel pin dramas, having the right tools can save the day—like a superhero for your fixture design. A laser alignment tool is your best friend, shining a light on misalignments that would otherwise lurk in the shadows, waiting to sabotage your project. Utilizing a dial gauge is also essential; this nifty device can detect even the tiniest deviations. The precision of these instruments can mean the difference between a flawless assembly and a construction comedy show where everything goes wrong.

Let’s not forget the vital role of custom dowel pins in your toolbox. If off-the-shelf options have led to epic fail moments, connecting with a reliable dowel pin manufacturer can interject a spark of ingenuity. Their expertise can help in crafting pins tailored to your specific needs, minimizing the chances of misalignments in the first place. Also, exploring techniques like reaming and using alignment jigs can enhance installation accuracy, effectively turning potential dowel catastrophes into seamless successes.

What Tools Will Save Your Day (and Sanity)?

When dowel pins decide to play hide-and-seek, having the right tools on hand can transform a potential engineering nightmare into a manageable task. First up is the trusty dowel pin insertion tool, which allows you to position and secure those fasteners with precision, reducing the angst that comes from misalignment. Pair this with a caliper to measure hole depth accurately, ensuring no more embarrassing moments of over or under-insertion. Imagine a scenario where you thought you were using standard pins, only to discover those custom dowel pins you ordered from your favorite dowel pin manufacturer were lurking in the toolbox, waiting to undermine your flawless assembly.

Next, invest in a high-quality drill bit tailored specifically for dowel hole drilling. Many professionals swear by brad-point bits, which provide clean, precise holes without the dreaded splintering that can ruin an otherwise good day. A little preparation goes a long way; using a dowel pin alignment fixture can save hours of realignment frustration. There’s nothing more satisfying than watching your parts fit together like they were intended by some divine intervention. Remember, having the right mix of tools not only keeps your sanity intact but can also shave off precious minutes from the assembly process — and who doesn’t want to finish early for lunch?

- A dowel pin extraction tool for when your dowels decide to play hard to get.

- A laser level to make sure everything is on the up-and-up and not asking for a side job as a funhouse mirror.

- A digital torque wrench to provide just the right amount of “oomph” without turning you into the Hulk.

- A tool organizer to keep your workspace less of a disaster zone and more of a zen garden.

- A roll of painter's tape to create straight lines and feign artistic skills when bored.

- Safety glasses, because no one wants to explain how they got a wood splinter in their eye—it's not a great icebreaker.

- A cup of coffee to fuel your frantic efforts; after all, a well-caffeinated mind is a productive mind.

3 Key Strategies for Ensuring Accurate Dowel Pin Installation

Ensuring that your dowel pins are in the right place requires a bit more than wishful thinking and crossed fingers. First, consider the use of a precise jig. A well-designed jig can eliminate that random guessing game akin to a toddler trying to fit shapes into the wrong holes. If the dowel pin manufacturer suggests a specific jig to accompany your custom dowel pins, take that as sage advice. Instead of counting on your ability to eyeball the alignment, you should rely on something that doesn’t have your questionable sense of direction.

Another strategy involves double-checking your measurements — a measure twice, cut once approach for the doweling elite. Invest in high-quality calipers and try to resist the urge to use that old ruler you found in your tool drawer. Mistakes often manifest in misaligned fixtures, leading to downtime or worse, costly rework. Don’t forget to consult manufacturer guidelines because following the standards can rescue you from a few comedic disasters that your workmates will probably not let you live down. Emphasizing accuracy at this stage will save you a headache later when attempting to fix your ill-placed dowel pins, turning potential chaos into constructive harmony.

How Can You Make Sure Your Pins Are in Perfect Harmony?

Achieving seamless dowel pin installation requires a steady hand and a touch of finesse, reminiscent of a surgeon performing a delicate operation. One effective strategy includes utilizing alignment jigs that can assist in ensuring precision during the installation process. A well-calibrated jig can increase your chances of success exponentially—think of it as your trusty sidekick on this dowel-driven adventure. The correct positioning not only ensures functionality but also prevents your fixtures from resembling a funhouse mirror at a carnival.

In addition, choosing the right dowel pin manufacturer plays a crucial role in installation harmony. Custom dowel pins can provide tailored specifications that fit specific project needs. Imagine having a pin that fits your hole tighter than your favorite pair of jeans after holiday feasting. With these custom solutions, you can minimize wobbling and misalignment issues that threaten to turn your carefully crafted projects into renovation nightmares. Investing in quality pins may incur a bit of upfront cost, yet in the long run, it saves both your time and sanity, allowing you to tackle even the trickiest fixture designs with unparalleled confidence.

Real-Life Case Studies

One memorable case involved an engineer who realized, a bit too late, that he had installed custom dowel pins spaced a full half-inch off. This minor oversight led to a delightful display of “dowel pin gymnastics”—a chain reaction of misalignment that spurred the entire fixture to wobble like a toddler on roller skates. After a few entertaining attempts to correct the errors with a hammer, he learned that sauntering into the office armed only with optimism is not the most effective strategy when dealing with assembly precision.

In another incident, a rookie technician received a shipment of dowel pins from a new dowel pin manufacturer, boasting cut dimensions that were suspiciously inconsistent. Not only did the poorly manufactured pins create assembly chaos, but they also transformed his workstation into an unintentional escape room. The fix took more than a mere adjustment; a full redesign was necessary, along with an educational seminar on the virtues of choosing reputable manufacturers. Ultimately, diligent research reduced future mishaps significantly.

What Can We Learn from These Misadventures?

Learning from the mishaps of dowel pin disasters can bring both laughter and insights. Take, for example, the engineer who mistakenly installed a custom dowel pin upside down, leading to a fixture that resembled a modern art installation rather than a functional tool. This blunder highlighted the importance of double-checking alignment and using proper tools, reinforcing the age-old adage: measure twice, cut once—and definitely check the orientation of your pins.

Another memorable case involved a dowel pin manufacturer that inadvertently shipped a batch with incorrect specifications. The resulting production errors cost the company time and resources, not to mention the countless perplexed faces of operators trying to assemble their fixtures. The takeaway here is clear: always verify product specifications before installation. Taking the time to ensure that everything aligns can save both your sanity and your project timeline, preventing future dowel-related disasters.

Maintenance Tips to Prevent Dowel Pin Problems

Regular maintenance is like a gym membership for your dowel pins—without it, they risk turning into floppy spaghetti rather than rigid precision instruments. One surefire way to keep your custom dowel pins in shape is to inspect them regularly for wear and tear. A simple visual check can help spot any misalignment or loosening in the fixtures due to poor installation. If you notice any signs of wear, don’t wait for a significant malfunction; act before your dowel pins decide to take an unscheduled holiday.

Staying ahead of dowel pin disasters also involves using quality materials from reputable sources. Always source your components from a reliable dowel pin manufacturer known for their quality assurance processes, which often adhere to industry standards. For example, the manufacturing process should include precise tolerancing to ensure compatibility with your fixtures. Don't skimp on quality. In the long run, investing in top-notch materials can prevent costly mishaps, saving mad engineers everywhere from hair-pulling moments of disbelief.

Conclusion

Every dowel pin disaster deserves a chance to teach us something valuable, even if the lessons come wrapped in laughter. Misplacement doesn't merely lead to clattering machinery; it can make even the most serious engineers giggle as they recall that one custom dowel pin saga where the pins decided to play hide and seek with the machinery. Remember, a well-placed dowel pin is like a good joke: it hits the mark when executed flawlessly.

Staying vigilant with maintenance can save you from the pitfalls of dowel pin mishaps. Routine checks every few months are essential; think of it as a spa day for your fixtures. A reputable dowel pin manufacturer often provides guidelines to help keep everything in top shape. Regular upkeep will not only prolong the life of the dowel pins but will also keep your sanity intact, which, in the world of machinery, is a commodity as rare as finding a needle in a haystack—except the needle is actually a misaligned dowel pin.

FAQS

What exactly is a dowel pin and why should I care?

A dowel pin is like the unsung hero of fixture design—small, round, and vital for keeping things aligned. If you don’t care about dowel pins, you might end up with a fixture that resembles modern art, rather than a functional tool!

How can I tell if my dowel pins are misaligned?

If your fixture looks more like a game of Jenga than a well-constructed piece of machinery, you might have misalignment issues. Just don’t try to pull it apart for a satisfying “thud” sound; that only works on a tabletop!

Can I fix misaligned dowel pins myself, or should I call in a professional?

If you have a toolkit and a sense of adventure, you might be the hero this dowel pin situation needs! Just be ready for some trial and error—think of it as a DIY reality show where you could win or lose a whole lot of sanity.

What are some common tools I might need for dowel pin installation?

You’ll want to gather some trusty sidekicks: a drill, a hammer (for persuasion), and maybe even a laser level to keep things in check. Just remember, a dowel pin’s greatest enemy is the rogue, uncalibrated drill!

Are there any maintenance tips to keep my dowel pins happy and healthy?

Absolutely! Regular inspections, keeping things clean, and ensuring they’re not overworked can help. Think of it as a spa day for your dowel pins—because even they deserve some pampering to stay aligned and fabulous!

What’s the funniest disaster story involving dowel pins you’ve heard?

Oh, there are many! One tale involves a dowel pin that was installed so crookedly, it turned the entire fixture into a makeshift rollercoaster. Let’s just say, it didn’t end well for the brave souls who attempted to use it!